Smart Tips About How To Build A Lift Shaft

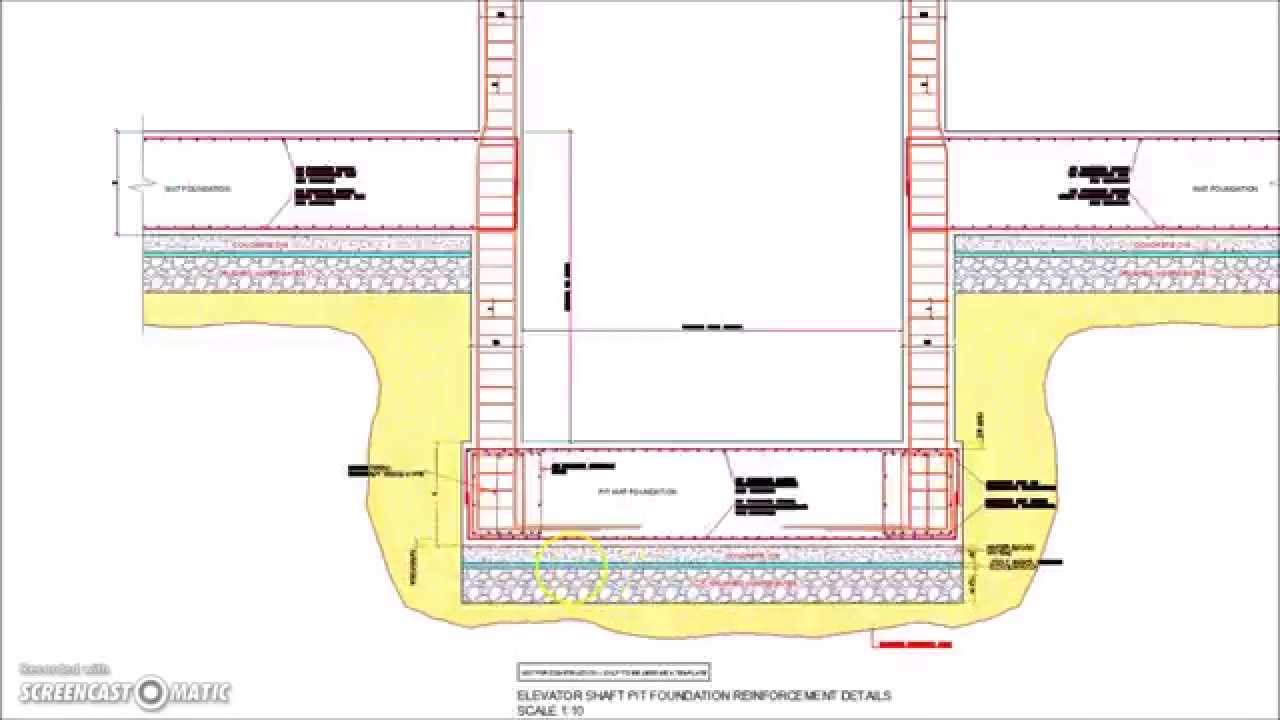

Generally 12 mm steel bars should be used with 4 inches center to center spacing.

How to build a lift shaft. Here at prns, we are well versed in the construction of lift shafts due to this, our process is both accurate and safe, ensuring the best. First, build the elevator shaft. View specifications for the different models and.

Shaft wall provides a lightweight, fire resistant structure to protect elements in confined spaces wherever access is limited to one side only. The requirements for lift shaft ventilation have been revised and are as follows. Pit height and lift openings, perimeter foun.

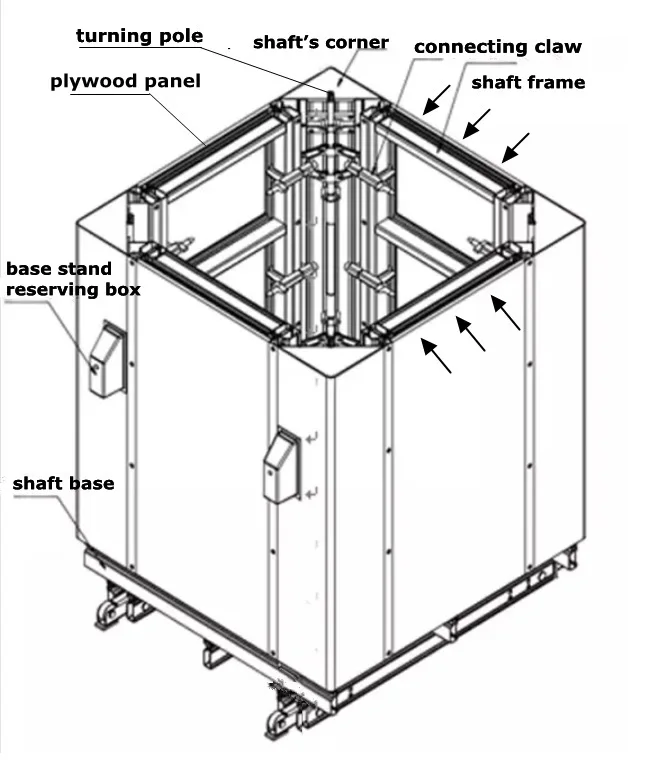

Now there is solution for quick and easy, but safe working inside elevator shafts, as 'fox1 scaffolds' brings you the top quality elevator shaft scaffold!saf. Use the shaft tool to place an opening that extends through the entire height of a building (or through selected levels), cutting through the faces of roofs, floors, or ceilings simultaneously. A common residential lift is usually 3’ wide by 4’ deep or 0.91 x 1.22 m in dimensions.

Call us on 0333 444 8052for advice & quotes. Shaft ventilation is now the responsibility of the building designer. Elevator shaft pit foundation reinforcement detailelevator shaft shear wall columns supported on mat foundation.

Our pick of the top models and manufacturers include: The spacing should be identical for main bars and distribution bars. Building a lift shaft now and installing the lift later.

We are finding more clients are wanting to build an elevator shaft at the build stage, and installing the lift later.